What is a cooling tower?

Cooling towers are common on commercial properties as part of large air conditioning systems. Cooling towers use evaporation to cool hot liquids generated by the system. Then the recovered liquids are re-circulated through the AC system. This is an effective way to cool fluids for air conditioners and make an AC system more energy efficient. However, there are several ways water is lost through a cooling tower system:

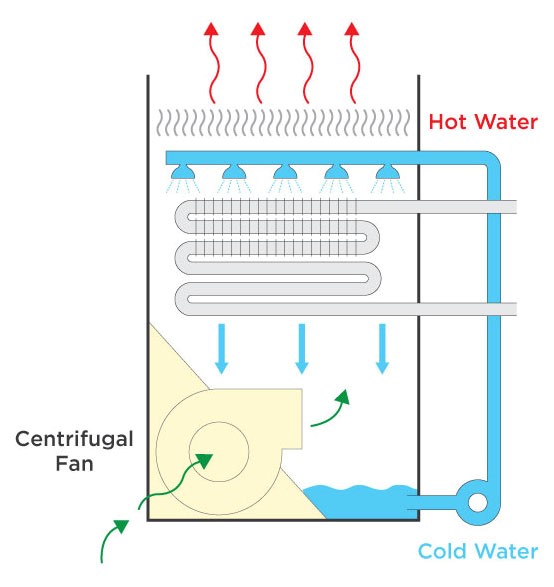

Typical colosed circuit AC cooling tower

Typical colosed circuit AC cooling tower

- Evaporation: Lost water due to evaporation when water hits hot pipes

- Drift – Lost water splashing or being blown out of the system by wind (When you walk by a cooling tower, you will often notice a little mist in the air as a result of drift.)

- Blowdown – After water evaporates out of the system, the remaining water contains increasingly high levels of minerals. Eventually, mineral-heavy water has to be removed via the blowdown line to avoid damage to the system.

Efficient Use of Cooling Tower Water

Cooling towers are an important part of an efficient commercial AC system, but they use a lot of water. Here are a few ways to minimize your water use.

Meter your Cooling Tower – Proactively identify system issues by metering water consumption. Increased consumption often indicates system issues. NOTE: Metering is also necessary if you want to save money by applying for an “evaporative credit,” offered by many utilities. You may already have metering in place through your chemical provider. Ask your cooling tower chemical provider if they already have meters, and if so, how you can obtain data from them.

Avoid Leaks and Over Fill – Cooling towers refill with fresh water when a float valve indicates that the water level is low. When that valve breaks, the system refills constantly. Check your meters regularly (manually, or through remote water management) to catch this quickly.

Find the Right Water Treatment Partner – The right partner will balance system operation with water efficiency through chemicals or increasing cycles of concentration. Since many vendors are paid based on the amount of chemicals they sell, you should select vendors based on “cost to treat 1,000 gallons of make-up water” and “highest recommended system water cycle of concentration.” Treatment programs should include routine checks of cooling system chemistry accompanied by regular service reports that provide insight into the system’s performance.

Maximize the Cycles of Concentration – Different systems can tolerate different cycles of concentration. Work with your cooling tower water professional (who provides chemicals for your cooling tower water) to see if your system could tolerate higher cycles of concentration without clogging or damage. Sometimes the use of different chemicals, including acid treatments, can allow for higher cycles of concentration.

Consider Retrofits that Allow for Higher Cycles of Concentration – Filtering your water, protecting it from sunlight and dust can all make your system more efficient. The Office of Energy Efficiency and Renewable Energy offers a good list of retrofit options on their website.

Use Recycled Water – Some properties have good options to use condensate water or other relatively pure water sources other than potable city water. Water quality and the minerals present in any water source should be considered before integrating with your system. The San Diego County Water Authority has put together a good guide on using recycled water in cooling towers.

Evaporative Credits

Many water utilities offer cooling tower credits to reduce sewage charges. You shouldn’t pay sewage charges for evaporated water. Contact your local utility to get a credit for evaporated water. You’ll need meters on your makeup and blowdown lines to quantify the credit.

NOTE: Some cities’ rebate programs require your cooling tower to be within a certain range of cycles of concentration to qualify for your evaporative loss credit.

Summary

Optimizing your cooling tower pays real dividends. It also extends the life of your equipment. To minimize your water costs:

- Meter to proactively identify issues causing water loss

- Meter to claim evaporative credits

- Avoid overfill spills by monitoring and maintaining your float valve

- Find a good chemical treatment partner

- Maximize cycles of concentration

- Explore retrofits that allow higher cycles of concentration

- Use recycled water

Banyan Water provides remote monitoring solutions that help you achieve your goals.

Glossary of Cooling Tower Terms, courtesy of the U.S. Department of Energy

Blowdown – Water discharged to remove high mineral content system water, impurities, and sediment.

Cycles of Concentration – This is an oversimplification, but think of this as the number of times water can be added to the system before needing to remove water through the blowdown. Higher cycles of concentration means a more efficient system.

Alternate, technical, and more accurate definition: Technical term used to describe the mass flow relationship between the amount of system feed water and the amount of blowdown sent down the drain. Also referred to as concentration ratio, cycles of concentration correlates to the effective use of water in your system to provide heating or cooling needs. High cycles of concentration are directly related to low levels of water loss from your system.

Dissolved Solids – The amount of dissolved minerals present in the water.

Drift – Droplets of water entrained in the air leaving the top of the tower, or blown from the side of the tower by crosswinds.

Make-up – Water supply needed to replace all losses due to evaporation, leaks, or discharge in cooling systems.